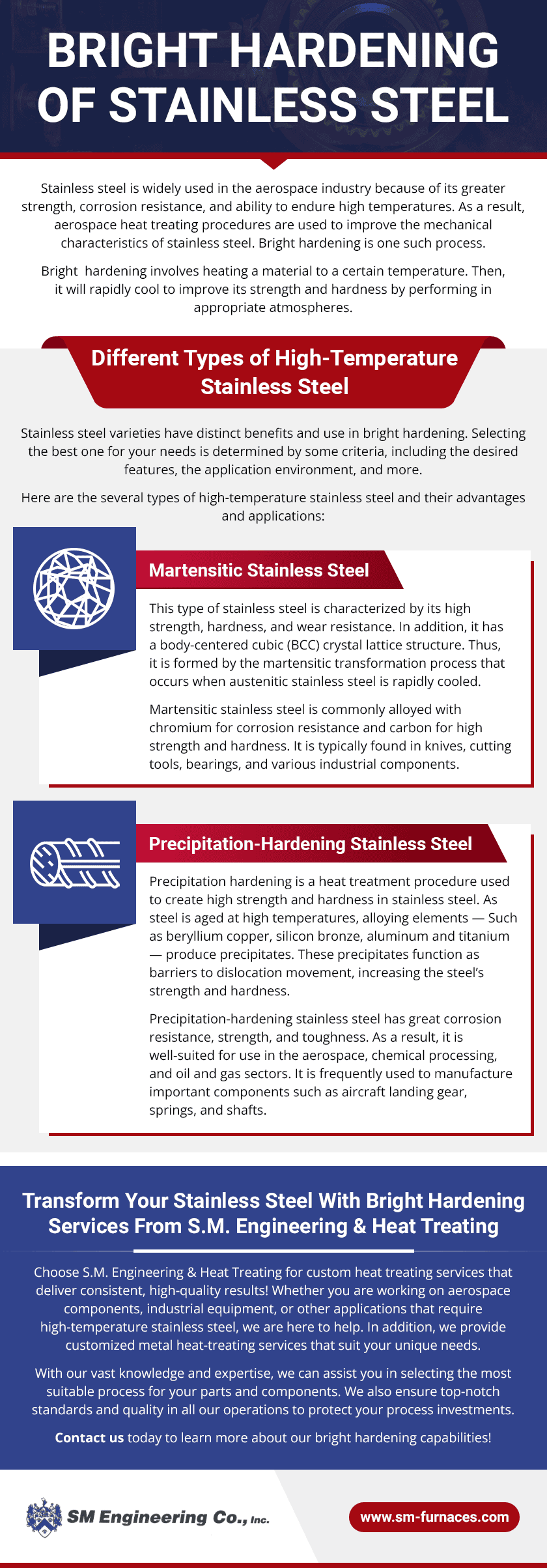

Stainless steel is widely used in the aerospace industry because of its greater strength, corrosion resistance, and ability to endure high temperatures. As a result, aerospace heat treating procedures are used to improve the mechanical characteristics of stainless steel. Bright hardening is one such process.

Bright hardening involves heating a material to a certain temperature. Then, it will rapidly cool to improve its strength and hardness by performing in appropriate atmospheres.

This article will examine the different types of high-temperature stainless steel used in bright hardening.

Different Types of High-Temperature Stainless Steel

Stainless steel varieties have distinct benefits and use in bright hardening. Selecting the best one for your needs is determined by some criteria, including the desired features, the application environment, and more.

Here are the several types of high-temperature stainless steel and their advantages and applications:

Martensitic Stainless Steel

This type of stainless steel is characterized by its high strength, hardness, and wear resistance. In addition, it has a body-centered cubic (BCC) crystal lattice structure. Thus, it is formed by the martensitic transformation process that occurs when austenitic stainless steel is rapidly cooled.

Martensitic stainless steel is commonly alloyed with chromium for corrosion resistance and carbon for high strength and hardness. It is typically found in knives, cutting tools, bearings, and various industrial components.

Precipitation-Hardening Stainless Steel

Precipitation hardening is a heat treatment procedure used to create high strength and hardness in stainless steel. As steel is aged at high temperatures, alloying elements — such as copper, aluminum, and titanium — produce precipitates. These precipitates function as barriers to dislocation movement, increasing the steel’s strength and hardness.

Precipitation-hardening stainless steel has great corrosion resistance, strength, and toughness. As a result, it is well-suited for use in the aerospace, chemical processing, and oil and gas sectors. It is frequently used to manufacture important components such as aircraft landing gear, springs, and shafts.

Transform Your Stainless Steel With Bright Hardening Services From S.M. Engineering & Heat Treating

Choose S.M. Engineering & Heat Treating for custom heat treating services that deliver consistent, high-quality results! Whether you are working on aerospace components, industrial equipment, or other applications that require high-temperature stainless steel, we are here to help. In addition, we provide customized metal heat-treating services that suit your unique needs.

With our vast knowledge and expertise, we can assist you in selecting the most suitable process for your parts and components. We also ensure top-notch standards and quality in all our operations to protect your process investments.

Contact us today to learn more about our bright hardening capabilities!