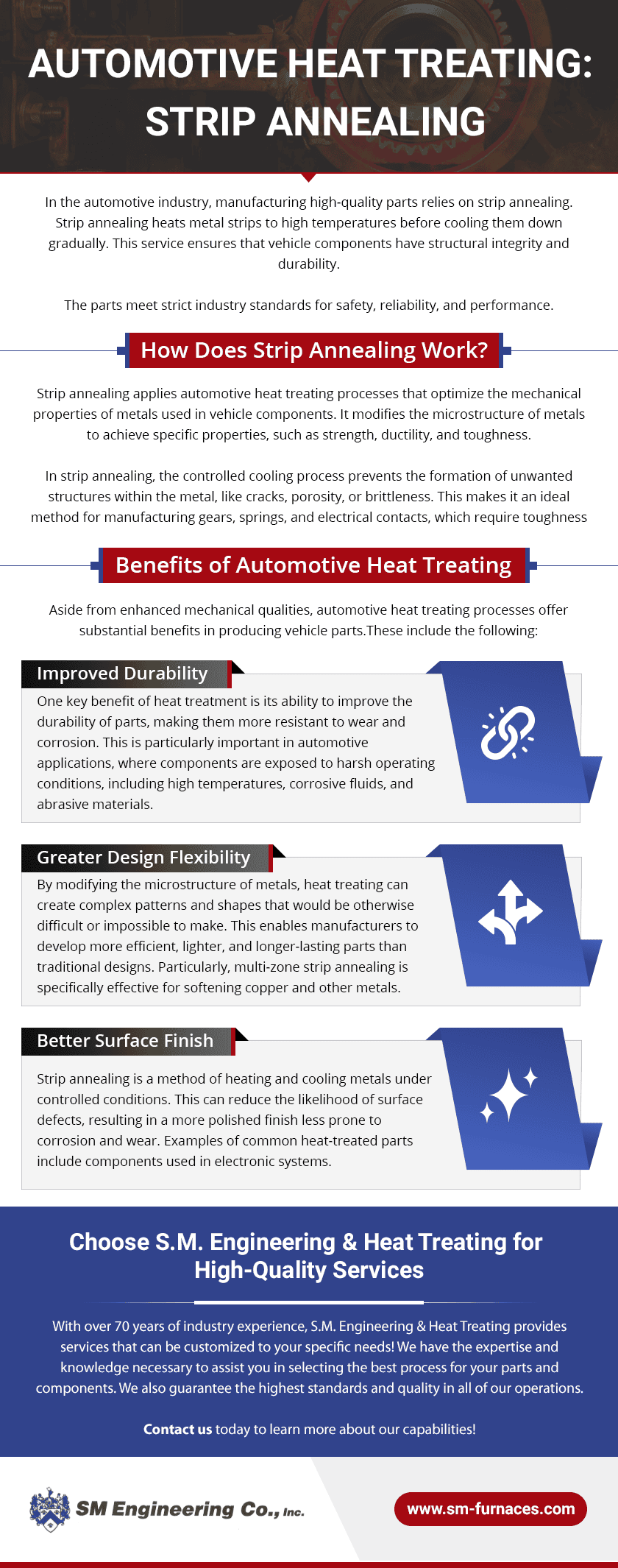

In the automotive industry, manufacturing high-quality parts relies on strip annealing. Strip annealing heats metal strips to high temperatures before cooling them down gradually. This service ensures that vehicle components have structural integrity and durability.

The parts meet strict industry standards for safety, reliability, and performance. This article will explore the benefits of strip annealing, explain how it works, and examine its applications.

How Does Strip Annealing Work?

Strip annealing applies automotive heat treating processes that optimize the mechanical properties of metals used in vehicle components. It modifies the microstructure of metals to achieve specific properties, such as strength, ductility, and toughness.

In strip annealing, the controlled cooling process prevents the formation of unwanted structures within the metal, like cracks, porosity, or brittleness. This makes it an ideal method for manufacturing gears, springs, and electrical contacts, which require toughness and ductility.

Benefits of Automotive Heat Treating

Aside from enhanced mechanical qualities, automotive heat treating processes offer substantial benefits in producing vehicle parts.These include the following:

Improved Durability

One key benefit of heat treatment is its ability to improve the durability of parts, making them more resistant to wear and corrosion. This is particularly important in automotive applications, where components are exposed to harsh operating conditions, including high temperatures, corrosive fluids, and abrasive materials.

Greater Design Flexibility

By modifying the microstructure of metals, heat treating can create complex patterns and shapes that would be otherwise difficult or impossible to make. This enables manufacturers to develop more efficient, lighter, and longer-lasting parts than traditional designs. Particularly, multi-zone strip annealing is specifically effective for softening copper and other metals.

Better Surface Finish

Strip annealing is a method of heating and cooling metals under controlled conditions. This can reduce the likelihood of surface defects, resulting in a more polished finish less prone to corrosion and wear. Examples of common heat-treated parts include components used in electronic systems.

Choose S.M. Engineering & Heat Treating for High-Quality Services

With over 70 years of industry experience, S.M. Engineering & Heat Treating provides services that can be customized to your specific needs! We have the expertise and knowledge necessary to assist you in selecting the best process for your parts and components. We also guarantee the highest standards and quality in all of our operations.

Contact us today to learn more about our capabilities!